1. CLOSER FIXING OPERATION ...read more>

1) Closer Operation:

The door closer contains a weight assembly comprising two in-line weights with an attached flow control valve. A nylon line, typically anchored to the door frame, (except in the case of middle meeting doors) passes through a pulley box inserted in the top of the closer tube and suspends the assembly in water. During installation of the closer the nylon line is terminated with an anchor lug that has a covering dress cap. The closer is designed to be mounted vertically onto the trailing stile of a sliding door by means of three, 10 gauge screws. As the door is opened the weight assembly is drawn up the tube, and then when the door is released the assembly descends slowly under the control of the valve to close the door. Three exchangeable clearance sleeves for the valve enable the closing speed to be adjusted somewhat if needed. Available weight assembly travel and hence door travel is 1200mm. (Complete installation instruction shipped with closer)

2. CLOSER PULLEY BOX ...read more>

2) Closer Attachment:

Lay the door closer down and withdraw the pulley box from the tube and slide off its back cover. Note how the nylon line passes over the foam wiper pad and the pulley wheel, then slide the pulley box completely off the line. Drawing the weight assembly slightly out of the tube, remove the now exposed screws, anchor lug and the two additional valve sleeves, then untie and discard the braided restraining cord. Holding the nylon line firmly, tilt the tube and gently lower the weight assembly down the tube to rest on the sealing bung. Now rethread the nylon line through the pulley box and reinsert the box into the tube. Then hold the closer vertically against the trailing door stile so that there is approximately 5mm clearance between the upper door track and the pulley box, and so that the nylon line, when extended horizontally, will meet the door frame at a suitable location (see Note 3). Mark and drill a 3.0 – 4.0mm hole in the door stile at the location of each of the three punched holes in the closer flange. Finally, leaving it engaged with the nylon line, withdraw the pulley box and fill the tube close to the top with tap or rain water (never pool water – it is corrosive). Then reinsert the pulley box and screw the closer to the door using the 10 gauge screws supplied.

3. NYLON LINE - ANCHOR LUG ...read more>

3) Nylon Line & Anchor:

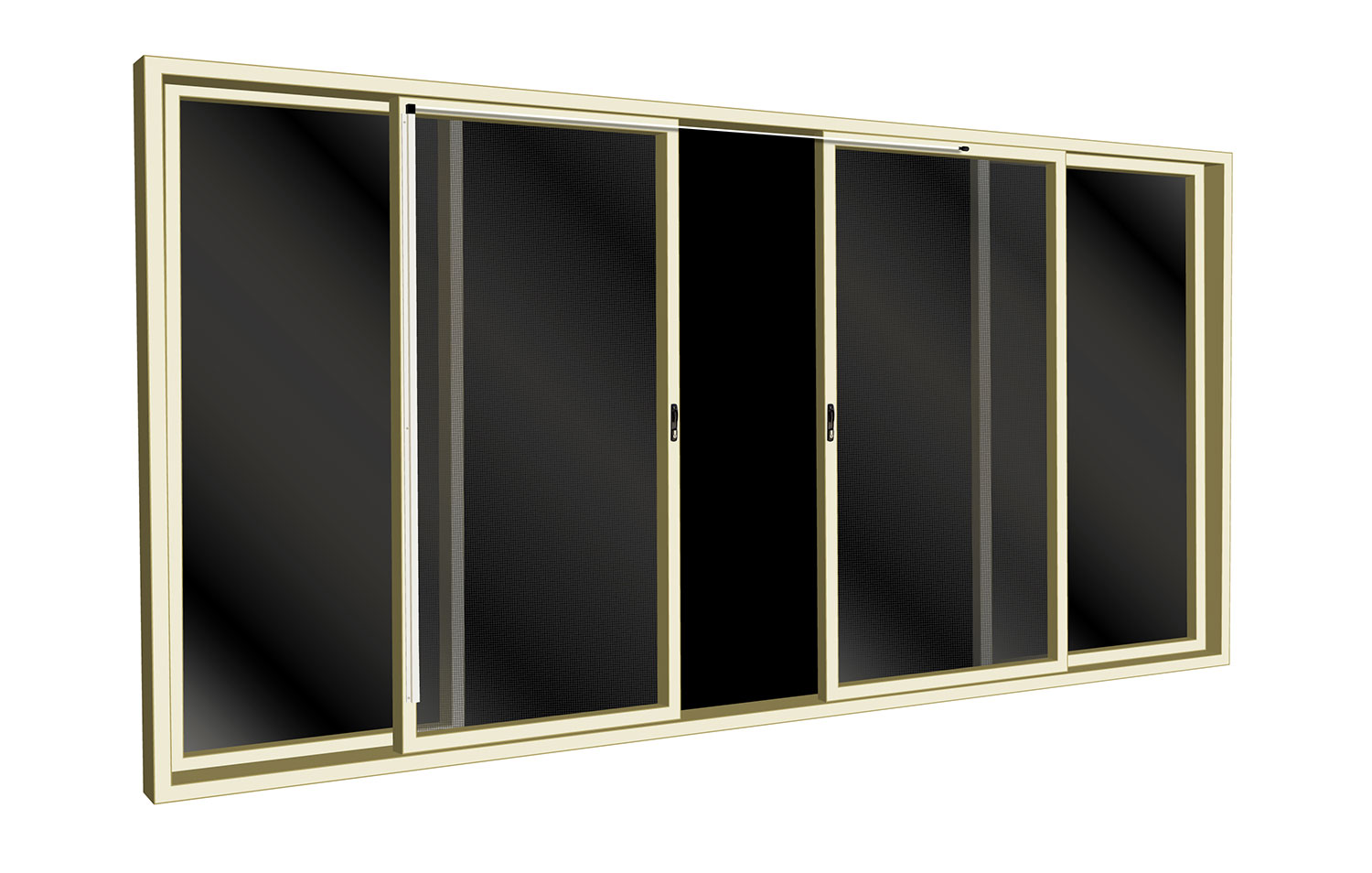

This picture is an example of a double door installation wherein, within limits, each door can be opened singly or together. As shown, the nylon line is anchored to the opposite door to that on which the closer is mounted, not to the door frame. With the weight assembly remaining at the bottom of the closer tube, hold the nylon line horizontally across to approximately one-third of the way onto the opposing door and, while ensuring that there is some free line, mark and drill a 3.0mm hole. Then insert but not tighten the supplied 8 gauge screw. As shown in the diagram feed the anchor lug cap and then the anchor lug itself onto the nylon line, well down towards the pulley box. Then pulling the line taut across to and over the screw, lift the weight assembly approximately 50 – 75mm off the bottom of the closer tube. Now tie a single knot in the line at the point where it had passed over the screw. Then, bringing the anchor lug back up the line to the knot, hook the lug onto the screw. For up to 1200mm wide doors it should be possible to individually open either of the doors fully without the weight assembly contacting the bottom of the pulley box. If there is contact a stop must be fitted to the upper or lower track to prevent any damaging impact. Since both doors cannot be fully opened together, to prevent impact it will be necessary to provide a stop to one or both doors. Where both doors have been partially opened the closer will close both doors although they are likely to move one at a time due to the combined track friction being too high – the door having even a slightly lower friction will move first. Where both doors need to be opened fully, e.g. for furniture access, any stops will need to be removed, and the anchor lug will need to be lifted off the anchor screw to disable the closer. When satisfied with the entire installation, trim the nylon line and snap the anchor lug cap onto the lug.

For a single door application the anchor screw needs to be located on the latch side of the door frame in such a position that the exposed tip of the screw will not prevent the door closing fully and latching, and such that there is sufficient clearance around the screw head to hook and unhook the anchor lug onto it with the cap attached. The lug and cap dimensions have been minimised to keep the required clearance low. Furthermore the cap has been designed to add strength to the eye of the lug in case the line is heavily tugged.

The AquaClose Sliding Door Closer is commonly known as the ‘Water’ Door Closer due to the fact that it uses a unique speed limiting valve operating within the water filled mounted closer tube.

The closing speed of the door is suppressed, resulting in a gently latching action. The AquaClose Water Door Closer is easily fitted to sliding security screen doors which conform to Australian Standards. It quietly and consistently closes your sliding doors for you, year in and year out.

In addition to its use as an automatic screen door closer, it has been extensively used Australia wide to satisfy swimming pool safety laws, which exist in all Australian states and are being adopted throughout the world. An automatic closing security screen door is an effective way of keeping young children from straying into the pool area where accidental drowning is a far too frequent cause of death.

It is available in all popular anodised and powder coated colours and is available through our Australia wide network of resellers/installers.

The AquaClose Sliding Door Closer is simply a great investment for any home and will improve your family’s lifestyle by increasing hygiene and health levels through keeping insects, flies, mosquitos and other vermin out of the home.

DISCLAIMER: State laws vary widely throughout Australia. Check with your local council to ensure your planned pool security solution complies with state laws.